QUALITY ASSURANCE

CNC Precision Engineering Quality Assurance

At Richmond Precision Services, we understand that quality assurance is critical in CNC subcontract engineering. That’s why our quality control process is fully tailored to each project – delivering precise, consistent, and certified components every time.

We are fully approved by BSI to ISO 9001:2015. We take great care throughout the manufacturing cycle from receipt of order to final delivery to ensure that our products meet the requirements in every way. We have many customers who take our products straight onto their production line without checking – ‘Right First Time’ is our business.

ISO 9001:2015 Certified CNC Machining

Custom Quality Reporting & Root Cause Analysis

We go beyond standard compliance. Our team conducts regular Root Cause Analysis (RCA) sessions to prevent recurrence of issues and drive improvement. We also provide:

FAIRs (First Article Inspection Reports)

ISIRs (Initial Sample Inspection Reports)

— available upon request to support customer-specific quality requirements.

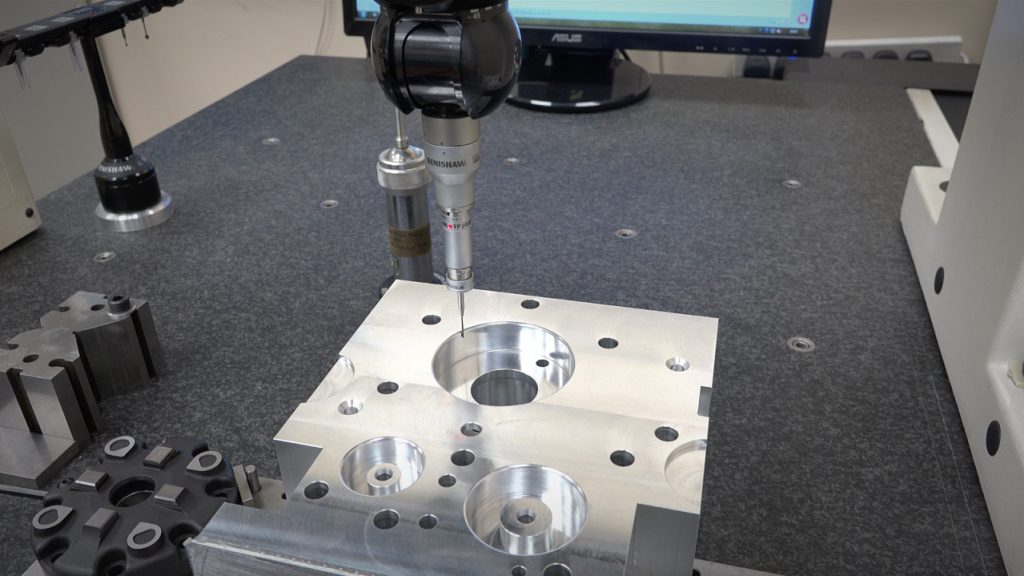

Precision Inspection Equipment

To maintain high standards, we use a combination of modern inspection technology and proven traditional tools, including:

CMM (Co-ordinated Measuring Machine)

Trimos Height Gauges

Verniers

Micrometers

Pin & Screw Plug Gauges

Ring Screw Gauges

Optical Projectors / Shadowgraphs

Thread Parallels

Get in Touch

Fill out the form below to get in touch or email sales@richmond-precision.co.uk or call 01225 706840